Self-acting flow controllers

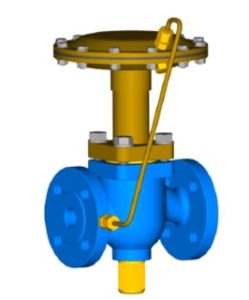

RQB – flanged controllers

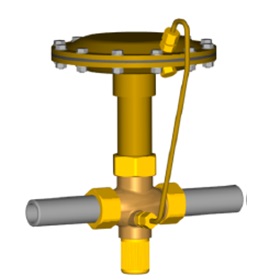

RQBm – screwed controllers

Applications

Self-acting flow controllers are used in heating and industrial systems. Designed for flow rate adjustment between 0.15 to 23 m3/h and compatible with cold and hot water up to 180ºC (RQB), up to 150ºC (RQBm) and non-flammable gases up to 80oC.

Features

- flow rate control,

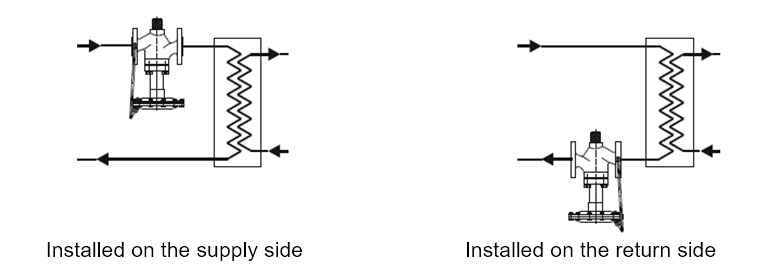

- installed on the supply or return side,

- high accuracy,

- maintenance-free,

- no external energy required.

Design

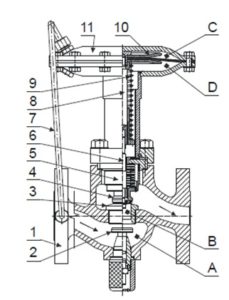

All self-acting flow controllers are medium-controlled proportional controllers. The valve disk (4) pressure is relieved by the relief unit (5) to guarantee stable regulation. The device has two components:

– control element (valve), including: valve housing (1), gland (2), seat (3), disk (4), relief unit (5), spindle (6);

– control unit (cylinder), including: impulse line (7), cylinder spindle (8), spring (9), cylinder disks (10), cylinder housing (11).

Principle of operation

The medium flows to the valve chamber (A). The clearance between the chamber (A) and (B) is set with a gland (2). Pressure in the chamber (A) is supplied to the cylinder chamber (C) via the impulse line (7). Pressure in the chamber (B) is supplied to the chamber (D) via the openings in the valve head (4). Differential pressure Δpm is determined by the spring (9). As a result of constant differential pressure between the chambers (C, D) a constant pressure drop Δpm is maintained between those chambers (A, B). As a result of constant differential pressure between the chambers (A, B), a constant medium flow rate is maintained at the valve. The valve head (4) is a control element. The regulated flow rate is set with a gland position (2).

- Flow rcontroller RQB (flanged)

- Flow controller RQBm (screwed)

- Flow controller RQBm contruction

Installing controller

Controllers must be installed on horizontal lines. Flow direction must correspond to the direction of the arrow on the housing. To ensure correct operation, the controller must be protected with a filter or a strainer.