Strainers for separating impurities

STRAINERS DN 15-200

Designed for retaining solids in media used in heating systems, heat distribution units, heating plants and air handling units. Strainers guarantee continuous operation of control systems, instrumentation, control and automation, heat exchangers, pumps and other system components. In large systems, including heat sources, strainers be used as by-pass filters operating at 5÷8% nominal water flow rate. Strainers are compatible with local water mains with high-rate filters for additional water filtering. The technical solutions used guarantee efficient medium filtering, easy installation and operation.

Features

- inertial separation,

- depositional separation,

- mechanical filtration,

- magnetic filtration for TerFOM and TerFM,

- air separation,

- low pressure loss.

Strainers type:

| Build \ Medium | water | glycol, brine |

| high-alloy steel + magnetic set | TerFOM | TerFOM-G |

| low-carbon steel + magnetic set | TerFM | TerFM-G |

| high-alloy steel | TerF | TerF-G |

| low-carbon steel | TerFO | TerFO-G |

Principle of operation:

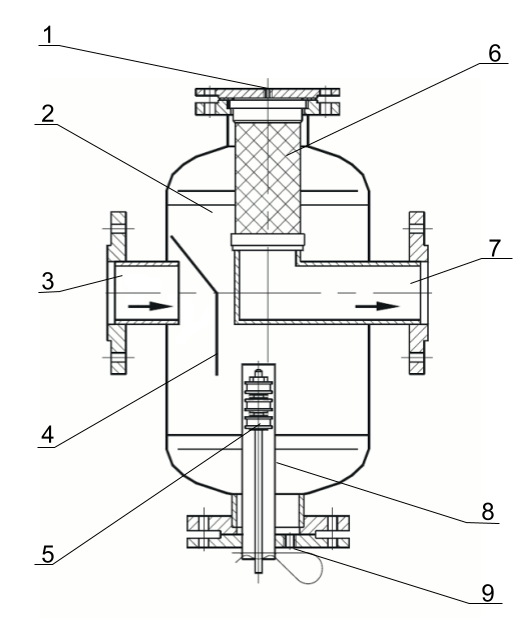

In DN15-150 strainers, the medium is transferred via an inlet port (3) and a baffle (4) to the bottom of the tank, into the zone affected by the magnetic field of magnetic inserts (5) installed in the ports (8) (TerFOM and TerFM only). The medium flow rate and pressure are reduced with simultaneous precipitation of solids and removal of air bubbles. Since a strainer (6) is installed in the top tank section, the blowdown is carried out at the entire tank capacity. The strainer for filtering medium is installed in the outlet port elbow (7). The air bubbles are removed from the strainer surface via a relief port (1) (automatic relief). The solids are removed via a drain port (9).

The main feature of the straineris low pressure loss (see hydraulic characteristic curves). All filtration stages guarantee that over 95% of all impurities are retained upstream of the strainer filter, mostly at the magnetic stack. The filter removes the remaining impurities. The analysis of the impurities from the magnetic stack shows that approx. 30÷40% are the paramagnetic substances (not affected by magnetic forces). The paramagnetic substance sedimentation effect is due to the entrainment of those substances by active particles and agglomeration.

Strainers with flange end connections:

– sanitary certificate.

– CE designation for T>110°C (does not apply to DN15, DN20, DN25 strainers)