Hydraulic Separators for refrigeration systems

Hydraulic Separators for refrigeration systems type SP-G

Hydraulic Separators for separating generator circuit and refrigeration circuit for medium and high power systems including one or several generators and one or several refrigeration circuits. Hydraulic Separators provide independent operation of both circuits without the need to balance the flow rates.

Features

- separating primary and secondary circuit

- maintaining independent mass flow in the generator and the refrigeration circuit

- eliminating flow rate balancing

- refrigerating medium blowdown

- refrigerating medium air purging

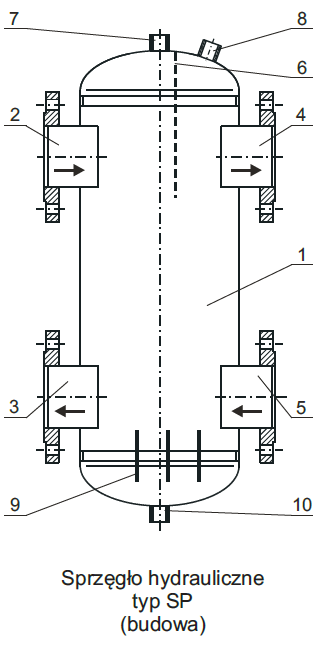

Design

Hydraulic Separator is designed as a low-carbon steel cylindrical tank with external paint coat finish. Tank shell (1) includes four ports. Inlet (2) and outlet (3) ports connect the generator circuits, whereas outlet (4) and inlet (5) ports connect the refrigeration circuit. The tank includes a perforated baffle (6) for easy air purging. To remove the air from the top tank section, the tank is fitted with an air relief valve port (7). The bottom tank section includes baffles (9) for easy blowdown. The separated solids are removed via a drain valve port (10).

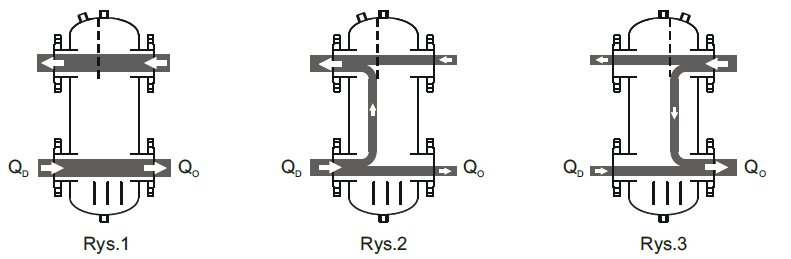

Principle of operation of Hydraulic Separator

Hydraulic Separators in the refrigeration system separates the primary and secondary refrigeration circuit. Three system operation modes are available:

– The volume at the refrigerating medium return is equal to the volume at the refrigeration system inlet. The quantity of heat delivered QD is equal to the quantity of heat received QO.

– With the secondary refrigeration circuit control valves closed due to a reduced cooling load QO, part of the stream flows along the low-loss header. The excess cold QD is returned and indicates that the generator power should be reduced or the generator stopped.

– If the cooling demand QO is higher than the generator power QD, the refrigeration system pumps force the return stream suction (Fig. 3). It increases the temperature of the stream supplying the secondary circuit. It indicates, that the generator power must be increased or another generator must be activated.

Principle of operation SP-G

Principle of operation SP-G

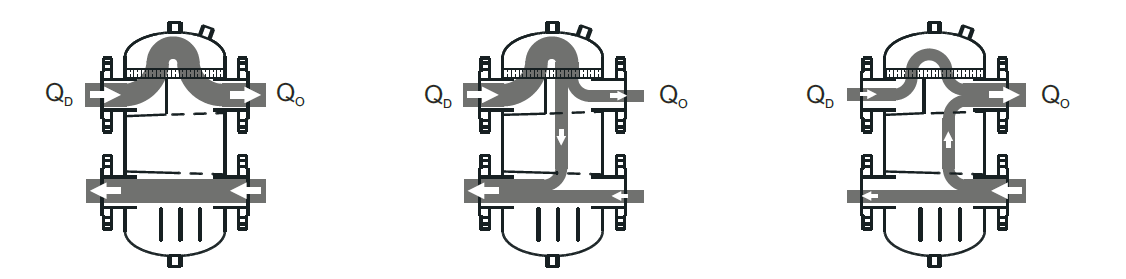

Principle of operation type SPP-G

Principle of operation type SPP-G