Air separators

Applications

Designed for removing air from water.

Used in heating systems at the highest temperature point (downstream of the boiler or heat exchanger). Air separators reduce system corrosion, extend pump life by reducing cavitation, flow noise and system noise.

Features

– automatic removal of air from heating water

– installed on horizontal lines

Design

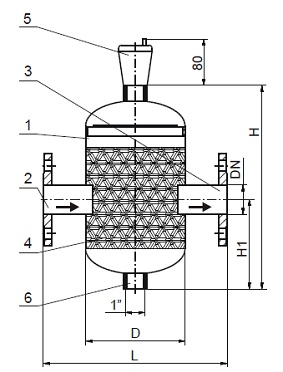

Low-carbon steel cylindrical tanks with external paint coat finish (acid-resistant steel version available). Inlet (2) and outlet (3) ports in the shell (1) for circulation pump. Special ring (4) insert for removing air from water. Automatic air relief valve (5) in the top section. Cleaning via drain valve port (6) in the bottom sectio

Principle of operation

Heating medium is discharged via port (2) to the tank. The flow rate is reduced inside the tank. The air bubbles and micro-air bubbles settle on the ring (4) walls. The air is removed to the top tank section and discharged via the automatic air relief valve (5). Air-free heating medium is discharged via port (3).

Technical specifications

Technical specifications

| Type | DN | Capacitydm3 | Rated temperatureoC |

Rated pressure bar |

Net weight kg |

Dimensions | |||

| D | L | H1 | H | ||||||

| SEP 15 | 15 | 1.1 | 110/150 | 6/10/16 | 3 | 108 | 265 | 105 | 210 |

| SEP 20 | 20 | 1.1 | 3.5 | 108 | 265 | 105 | 210 | ||

| SEP 25 | 25 | 1.1 | 3.8 | 108 | 265 | 105 | 210 | ||

| SEP 32 | 32 | 1.1 | 4.4 | 108 | 265 | 105 | 210 | ||

| SEP 40 | 40 | 4.6 | 11 | 159 | 295 | 120 | 305 | ||

| SEP 50 | 50 | 4.6 | 12 | 159 | 295 | 120 | 305 | ||

| SEP 65 | 65 | 4.6 | 13 | 159 | 295 | 120 | 305 | ||

| SEP 80 | 80 | 30 | 27 | 273 | 450 | 195 | 600 | ||

| SEP 100 | 100 | 30 | 30 | 273 | 450 | 195 | 600 | ||

| SEP 125 | 125 | 47 | 52 | 324 | 500 | 300 | 780 | ||

| SEP 150 | 150 | 47 | 55 | 324 | 500 | 300 | 780 | ||

| SEP 200 | 200 | 130 | 80 | 457 | 667 | 410 | 980 | ||

| SEP 250-500 | special version for DN250 to DN500 diameter | ||||||||

– PN16 flanges

– flange dimensions as per PN-EN 1092-1

mark as per relevant regulations (depending on T, p, V).