Products:

Filtrations

Strainers Contaminations separators Air separators Droplet eliminatorsCircuit Separators

Hydraulic Separators for boiler circuit Hydraulic Separators for refrigeration systems CollectorsPressure vessels

Pressure Vessels and Storage Tanks Expansion VesselsControlers

Stabilizing and top-up equipment Valves and ControlersTERMEN » Offer » Stabilizing and top-up equipment » Automatic charge top-up device BUW

Automatic charge top-up device BUW

Automatic charge top-up device

BUW

BUW-G – for glycol systems

Applications

Designed for control and automatic water top-up in the central heating charge supplied with mains water or water from the heat distribution return.

Widely used in boiler rooms and heat distribution units, in particular in high buildings and central heating systems with expansion vessels. Compatible with glycol (air conditioning systems).

Features

– topping-up water in heating systems

– topping-up chilled water (water/glycol) in refrigeration systems

– preventing pressure drop below preset value

Design

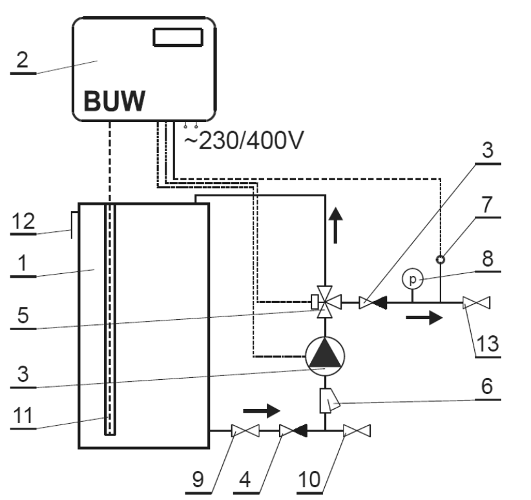

The device includes a tank (1) mounted on the base. A cabinet with control system (2) is installed over the tank. All control elements pump (3), solenoid valve (5), water meter (7), pressure sensor (14) depending on the version are i nstalled over or by the top-up water tank (1).

The pump (3) is also available in glycol compatible version. Top-up system is not installed and the tank dimensions (1) are selected accordingly.

Principle of operation

Static system pressure can be set in the control system (2). Pump (3) maintains the minimum system pressure. System pressure drop to its minimum value is read by the pressure sensor (14) and transmitted to the control system (2). Control system (2) activates the pump (3) to refill the medium to the set static pressure level. Level sensor (11) maintains the minimum required water level in the tank (1).

As the control system (2) receives a minimum level signal, the solenoid valve (5) opens and the medium is topped-up to the level maintained by the level sensor (11). The tank is protected against exceeding the maximum level with an overflow (13).

If the system is filled with glycol, the medium is topped-up by the user. If the glycol level in the tank (1) reaches the minimum level, the control system (2) receives a minimum level signal via the level sensor (11) and indicates that the medium must be topped-up.

Design

The device includes a tank (1) mounted on the base. A cabinet with control system (2) is installed over the tank. All control elements pump (3), solenoid valve (5), water meter (7), pressure sensor (14) depending on the version are i nstalled over or by the top-up water tank (1).

The pump (3) is also available in glycol compatible version. Top-up system is not installed and the tank dimensions (1) are selected accordingly.

Principle of operation

Static system pressure can be set in the control system (2). Pump (3) maintains the minimum system pressure. System pressure drop to its minimum value is read by the pressure sensor (14) and transmitted to the control system (2). Control system (2) activates the pump (3) to refill the medium to the set static pressure level. Level sensor (11) maintains the minimum required water level in the tank (1).

As the control system (2) receives a minimum level signal, the solenoid valve (5) opens and the medium is topped-up to the level maintained by the level sensor (11). The tank is protected against exceeding the maximum level with an overflow (13).

If the system is filled with glycol, the medium is topped-up by the user. If the glycol level in the tank (1) reaches the minimum level, the control system (2) receives a minimum level signal via the level sensor (11) and indicates that the medium must be topped-up.

Set designation

Please specify the device type, required working pressure, water loss, system power and BMS output when placing an order.

BUW type devices are also available to order.